At Base Brenner Tunnel, to support each team involved in the enterprise, the most modern monitoring and active safety technology has been chosen: AME’s EGOpro SAFE Tunnel system.

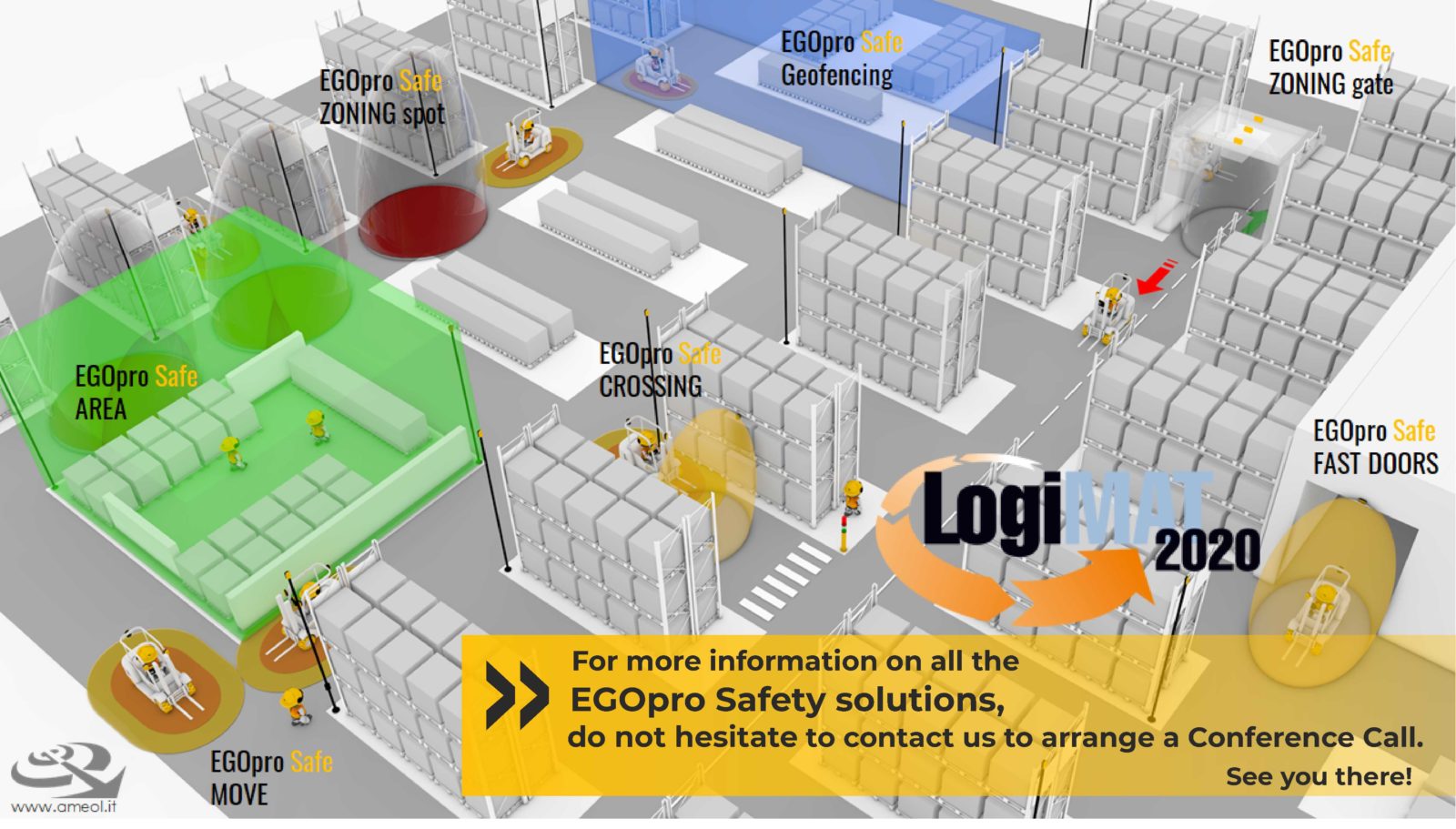

Advanced Microwave Engineering was chosen by BTC to handle the active safety aspect at the Brenner Base Tunnel construction site using the integrated solution: EGOpro Safe Tunnel. EGOpro Safe Tunnel is a complete, integrated and reliable solution, that allows various modules to be managed such as access control and tracking operators in transit to and from excavation faces, tunnel communication management, closed circuit video camera systems, traffic sign precedence, alarms and environmental sensing. The solution is based on identifying and controlling the presence of personnel, and detecting and storing the number and position of operators, in real time, inside the tunnel. Everything is done automatically for more efficient and more timely management of emergency procedures and evacuation. Additionally, operators can receive information in real time on any potential hazardous situation such as, for example, detecting when the maximum time window in a zone has been exceeded (that is, when an operator or a group exceeds the working time as set out in the safety procedures). An alert message can be sent to selected profiles for safety management purposes.

AME at the Brenner Base Tunnel construction site handles:

• ACCESS CONTROL AND TRACKING (People and vehicle access control – Operator tracking in real-time inside the tunnel – CCTV system)

• VOICE COMMUNICATION (GSM inside the tunnel – Radio UHF -TETRA)

• INFRASTRUCTURE (Single-mode fibre optic network system)

• ALARMS AND SOS MANAGEMENT (SOS emergency call box – Variable message signs – Audio signals)

• ENVITOMENTAL MONITORING (Fibrolaser)

The system, running on web-based software, provides the control room with an overview of the situation and displays, in real time, the position and the identity of each operator, as well as monitoring the status of any alarms. In addition, for direct monitoring on-site, a display can be used that shows the number of operators in the tunnel and can message them instantly.

#Tunnel #Safety #BBT #BTC #safetyfirst #tracking #innovation #Accesscontrol #voicecommunicationsystem #tunneling

#Tunnel #Safety #BBT #BTC #safetyfirst #tracking #innovation #Accesscontrol #voicecommunicationsystem #tunneling #sicurezza #ActiveSafety