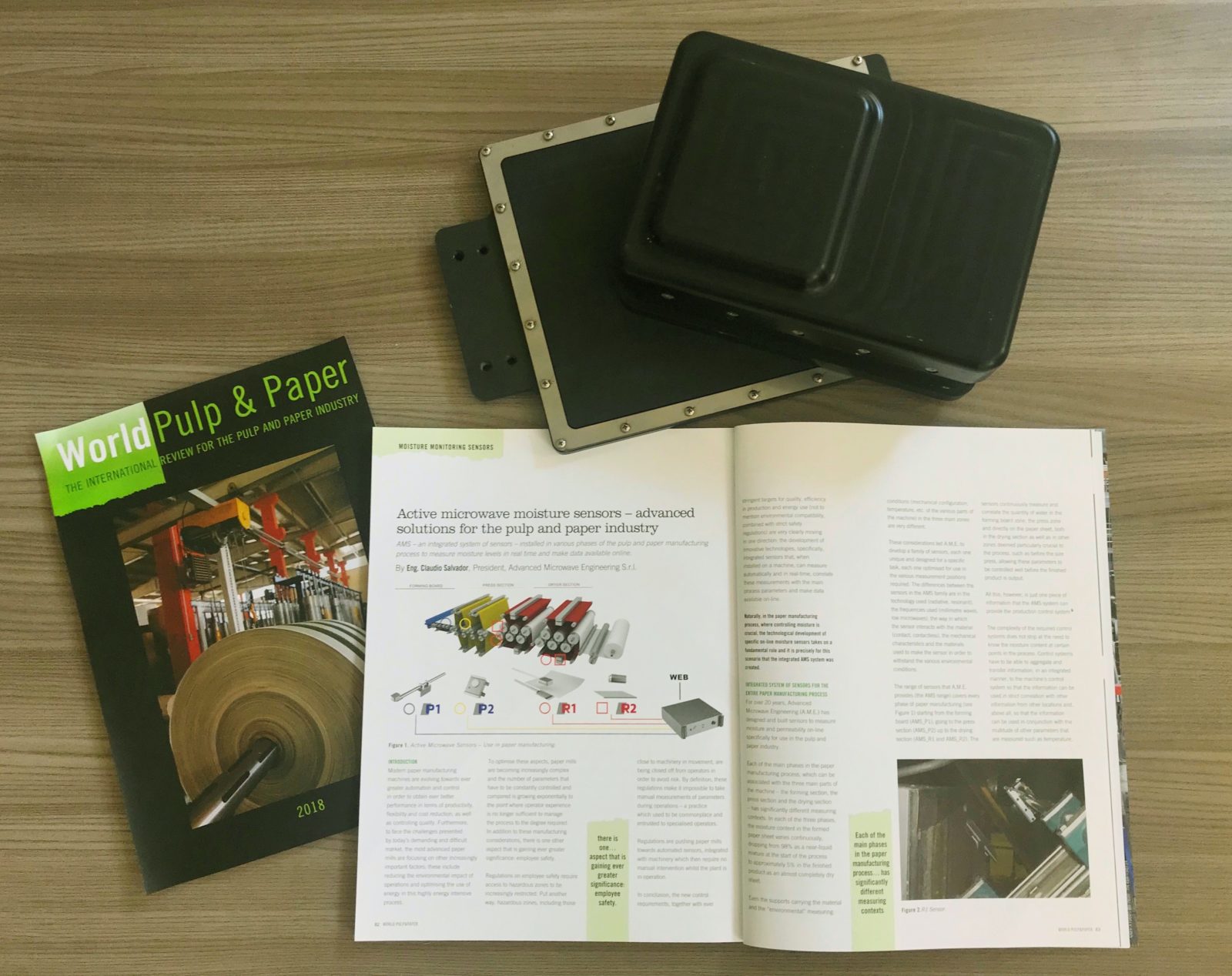

Eng. Claudio Salvador submits the R1 sensor – non contact on line moisture measurement – in an article on Word Pulp & Paper 2018.

ACTIVE MICROWAVE MOISTURE SENSOR

AMS | an integrated system of sensors – installed in various phases of the pulp and paper manufacturing process to measure moisture levels in real time and make data available online.

INTEGRATED SYSTEM OF SENSORS FOR THE ENTIRE PAPER MANUFACTURING PROCESS

The range of sensors that A.M.E. provides (the AMS range) covers every phase of paper manufacturing starting from the forming board (AMS_P1), going to the press section (AMS_P2) up to the drying section (AMS_R1 and AMS_R2).

The sensors continuously measure and correlate the quantity of water in the forming board zone, the press zone and directly on the paper sheet, both in the drying section as well as in other zones deemed particularly crucial to the process, such as before the size press, allowing these parameters to be controlled well before the finished product is output.

All this, however, is just one piece of information that the AMS system can provide the production control system.

R1 CONTACTLESS MOISTURE METER FOR PAPER SHEETS OR PULP

AMS_R1 represents real innovation in microwave sensors in terms of measurement technology and, above all, because it does not need to bein contact with the material to be measured. Being able to use the sensor in the most disparate types of production – from tissue paper to pulp – two of the most stringent requirements were: firstly, to have a wide active range of measurement (0-1500 gr/m2); and secondly, to have extremely high resolution and accuracy (< 0.1 g/m2)….