IREAD4.0 project aims at developing an integrated HW/SW system (Cyber Physical System), for the monitoring and automatic management of pallets and forklifts, in large warehouses characterized by high rotation index products.

The proposed system will be optimized for warehouses larger than 10000m2 with an average goods handling of more than 1000 pallets/day. Such warehouse scenarios require for technological solutions that are reconfigurable, low-cost, flexible, as well as easily scalable with respect to warehouse size, goods variety and required spatial resolution for the pallet localization. Above requirements can be satisfied by exploiting the (passive) RFID technology at UHF band.

An HW/SW platform will be implemented in each forklift, and it includes an RFID reader, reconfigurable antennas, an IMU device (inertial measurement unit), speed and proximity sensors, a local processing unit, a radio-based safety system, a human interface device. Any commercial forklift will be transformed in a “Smart Forklift” that will allow for the effective implementation of a number of functionalities. Among them, it is worth mentioning:

- self-localization inside the warehouse scenarios thanks to a set of passive fixed transponders that are spread out in the scenario;

- data temporary storage and data transmission anytime that the forklift is in the WiFi coverage area (data-mule service);

- pallet localization inside the storage bays;

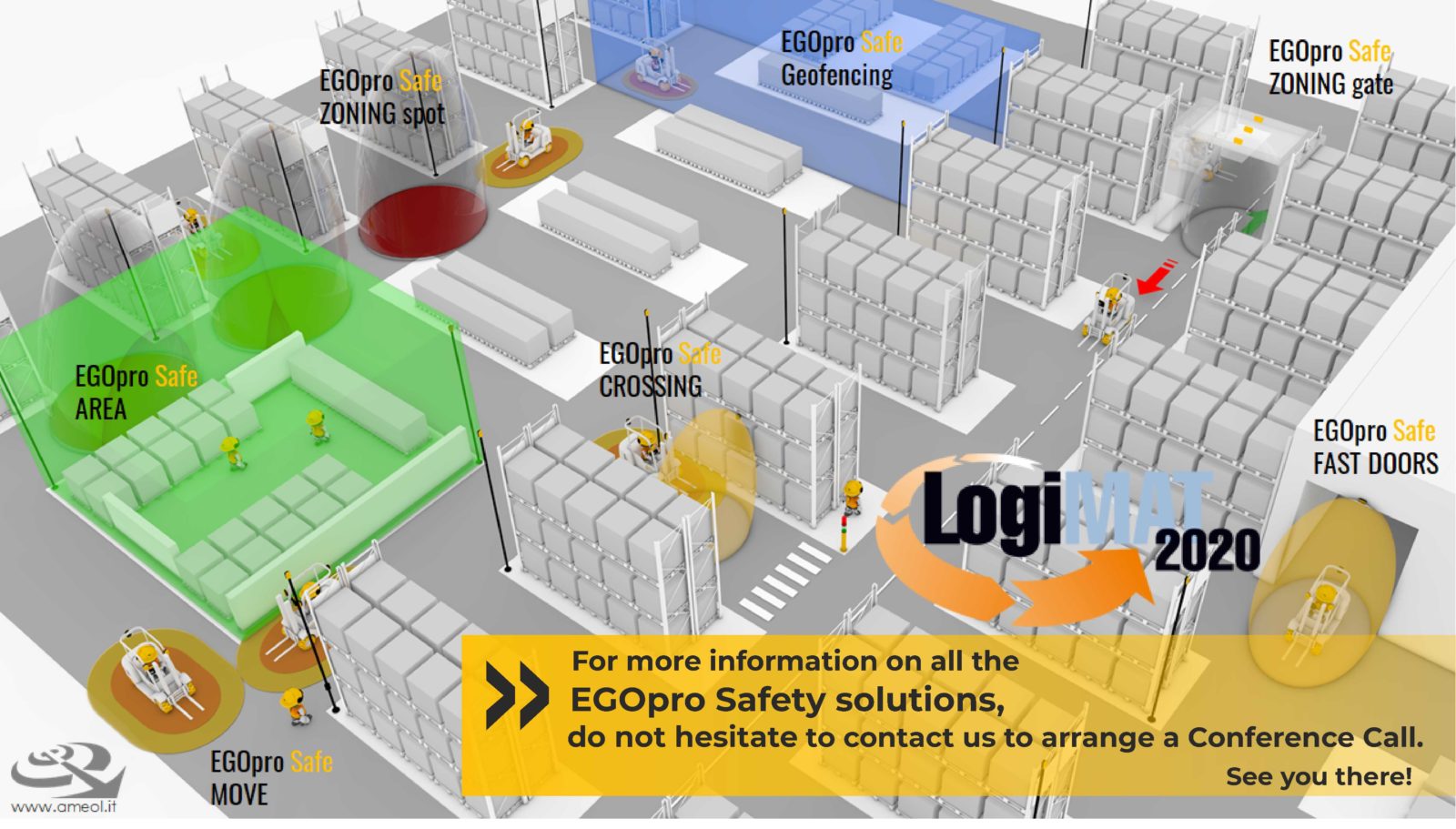

- identification of the forklift position in case of near-missing events (avoided collisions between forklifts, or forklift and operators).

Moreover, data acquired by the Smart Forklifts, once combined with data available at the manufacturer ERP (Enterprise Resource Planning), will be exploited by a WMS system (Warehouse Management System) aimed to implement some additional services:

- optimization of the forklift paths and pallet storage inside the warehouse (routing/storage optimization);

- forklift predictive maintenance;

- classification and processing of near-missing event data;

- automatic check of the loading operations at the loading docks or production-line ends;

- automatic real-time inventory;

- virtual geo-fencing;

- messaging between the management system and the forklift operator.